Baldwin offers non-contact precision spray systems designed to save time, money and valuable resources.

Our precision spray application systems are unlike any other solution available today in terms of eco-efficiency and safety.

Baldwin’s precision spray systems for finishing and remoistening utilize non-contact spray technology, meaning that you will always have a controlled optimal coverage of the exact amount of liquids for reaching specific characteristics of the fabric.

Since the exact required amount of water and chemistry is always applied – no more and no less, the water consumption can be cut by as much as 50%. This contributes to a considerably enhanced productivity in your finishing process.

Whether dealing with textiles, non-wovens or technical textiles, the precision spray technology is able to process a wide range of low-viscosity water-based chemicals, such as softeners, anti-microbial agents, water repellents, oil repellents, flame retardants, and more.

Cut chemicaLS by 50%

REDUCE ENERGY BY 50%

REDUCE WATER USE BY 50%

INCREASE PRODUCTIVITY BY 80%

Baldwin’s solutions enable fabric producers to immensely reduce their chemical and water consumption while speeding up production times and making it possible to eliminate entire steps from the textile manufacturing process, like drying and bath changeovers required when switching between fabric colors to avoid color contamination.

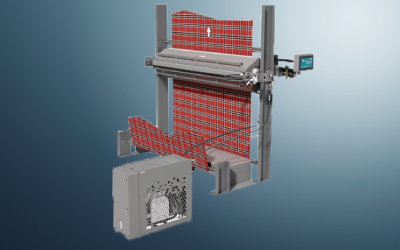

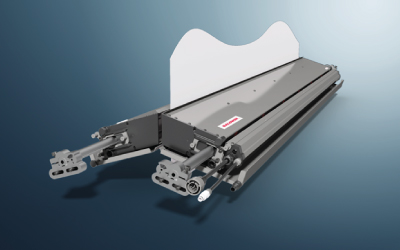

Baldwin offers two key precision application solutions for fabric makers - TexMoister G2, which offers single- or dual-sided application of water to fabrics, and TexCoat G4, which offers single- or dual-sided application of chemistries like fabric softeners, antimicrobial agents, waterproofing repellents and others to textiles. Both systems use precision-valve spray technology - which never actually touches the fabric, a key feature.

The technology enables either a light topical coating on lightweight fabrics or a deep penetration on heavyweight fabrics in a manner that reduces chemical and/or water consumption by 50% or more when compared with traditional padding/Foulard/bath methods. The non-contact technology totally eliminates the chemical waste stream associated with foulard changes.

Baldwin also provides the Rotor Spray system from Ahlbrandt - A Baldwin Technology Company - this system uses rotary discs to achieve an even spray. The Rotor Spray systems meet the demands for very precise low-level application required in the film and tissue sectors.

Additionally, Baldwin offers the market’s most efficient Corona/Plasma Treatment Systems with high-performance electrodes ensuring effective surface treatment for enhanced dyeing, coating, and adhesion on a variety of textile materials. The slim design enables easy integration and retrofit into existing production lines, and our features allow for fast and easy service.

Our solutions are frequently used in upholstery fabric manufacturing; the manufacturing of anti-microbial fabrics intended for on-skin contact; the manufacturing of water-repellent fabrics used for jackets, raincoats, backpacks, and similar waterproof garments and items; laminated fabrics like those used for swimwear, dresses and intimates; and softened fabrics that are intended for apparel like t-shirts and pants.

![Inside the Factory at Pincroft Dying & Printing [Customer Testimonial]](https://images.squarespace-cdn.com/content/v1/5c81551990f9045d9cf82ff0/1676927675125-SVOS6G5RECRRGPLS9QES/2023-02-20_16-05-31.jpg)